USBF Clarifier (Upflow Sludge Blanket Clarifier)

USBF Clarifier (Upflow Sludge Blanket Clarifier)

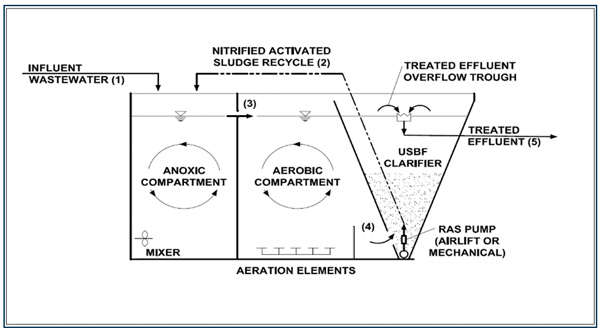

Utilizing the USBF Clarifier (Clarifier), ECOfluid’s technology achieves exceptional wastewater treatment efficiency, including biological nutrient removal (BNR), all while maintaining competitive capital and operating costs. Similar to the Modified Ludzack-Ettinger (MLE) process, the technology features anoxic and aerobic compartments, and it recycles nitrified activated sludge from the bottom of the Clarifier situated within the aerobic compartment, back to the anoxic compartment. The arrangement facilitates the removal of nitrogen through nitrification and denitrification, and phosphorus through biological uptake processes.

The operation of the plant is straightforward and self-regulating.

Influent wastewater (1) first enters the anoxic compartment of the bioreactor where it mixes with nitrified activated sludge recycled from the bottom of the Clarifier (2) and provides the carbon source necessary for denitrification. The mixed liquor then moves in a plug flow manner into the aerobic compartment (3).

After aeration, the mixture of microbial cells and water enters the Clarifier at the bottom (4). As the mixture rises within the Clarifier, the upward velocity decreases due to the increasing cross-sectional area. This reduction in velocity causes the flocs of cells to become stationary, effectively forming a filtering media. Through contact and agglomeration, the flocs grow larger and heavier and eventually descend to the bottom of the clarifier, from where they are subsequently recycled back into the anoxic compartment.

The clarified effluent overflows into a treated effluent trough and is discharged from the system (5).

Phosphorus is reduced through biological phosphorus uptake (also referred to as luxury uptake), where cells store excess phosphorus beyond their immediate needs. Unlike traditional settling clarification, the Clarifier maintains oxide conditions, which promote phosphorus retention by the cells and phosphorus is then removed along with the waste sludge.

The USBF Clarifier’s fluidized bed filtration process allows for operation at elevated MLSS concentrations, and it offers greater clarification efficacy compared to conventional settling clarification, as even very fine particles are filtered out.

Beneficial Features

- Mechanically simple, gravity flow- through with minimal count of moving parts

- Biological nutrient removal (BNR)

- Self-regulating hydraulic flexibility capable of handling swing flows

- Capital and operating costs effective

- Fluidized bed filtration efficiency

- Modular, expandable, compact

- Reduced odor and noise